Canada’s first carbon capture cement plant launches in Ontario

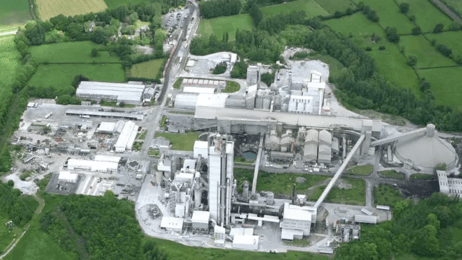

Carbon and resource utilisation firm Carbon Upcycling Technologies and cement manufacturer Ash Grove have broken ground on a first-of-its-kind commercial carbon capture and utilisation facility at Ash Grove’s cement plant in Mississauga, Ontario.

Dubbed Carbon 1 Mississauga, the project will permanently sequester carbon dioxide from the cement kiln at the facility and utilise it to produce up to 30,000 tonnes of low-carbon supplementary cementitious materials a year.

The project will utilise Carbon Upcycling’s CUT CO2 system, which captures CO2 directly from flue gas and reacts it with industrial byproducts inside a modular reactor.

The process accelerates mineral carbonation, embedding the CO2 permanently in solid form and creating performance-enhancing carbonated supplementary cementitious materials that can replace up to 50% of clinker – a key binding component – in cement.

Serge Schmidt, President of Ash Grove, said the project signals how to decarbonise one of the world’s most essential industries.

Cement is the most widely used substance on Earth after water. It is responsible for around 8% of global carbon dioxide emissions. The cement industry is one of the most polluting manufacturing sectors.

Ash Grove has set a target to reduce its absolute CO2 emissions by 30% by 2030 and a goal to reach net zero by 2050.

The Carbon 1 Mississauga project has been awarded up to $10m in federal funding. CRH Ventures, the venture capital unit of building materials company CRH, which is also the parent company of Ash Grove, has also invested in Carbon Upcycling.